|

|

|

| |

| The

humble spade, once the main tool of thousands of small Irish farmers,

many of whom may have been too poor to afford a horse, to work the land

and feed their families their only In earlier times the spade was made by the local blacksmith, communities then were more or less self sufficient each town or village having craftsmen catering for the needs of the locality. This is probably the main reason for the diversity of spade types seen across Ireland, although the soil type had a bearing on this also, Mayo and the western counties favoring a narrower blade for their stony soil. The nineteenth century saw the transport

system expand enormously, using the canals

and later the railways

it was possible to economically dispatch goods to almost any part of the

country. A few intrepid individuals recognized the potential of industrializing

the making of spades, and opened spade mills, one such was Patterson's

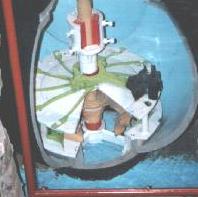

See types and distribution of mills in Ireland. Nearly every item of machinery in the mill underwent some form of restoration, some of the shafting was replace and new bronze bearings were cast and machined This image is of a plaster mock up of the turbine case, the old turbine is inside with a cut away section showing the working parts. The original turbine was an American Lefell, apparently the company are still in operation, the turbine was examined at the outset and found to have suffered excessively wear and corrosion, it was decided to use it as a template and make an exact working replica. More information Spade maker Colin Dawson forms a spade on the trip hammer. All the parts of the spade were made by Patterson's including the shafts which came in as lengths of square ash, which were rounded in a machine similar to a powered pencil sharpener. The heated billet which is shaped like a miniteue spade but is about one inch 25mm thisk, is drawn out using the tilt hammer, this process requires several heats. It is important that the faces of the hammer and anvil which are the same shape and size dont strike each other, when the spade maker has finished with the hammer he deftly places a wooden prop under the hammer head when it reaches the top of its up stroke preventing it from falling. When he wants to use the hammer again he places the hot billet on the anvil and knocks the prop out with a hammer. The bellows in Pattersons Spade Mill are The type of bellows illustrated here were common in blacksmiths shops throughout the country. They had two chambers and were made from three pieces of wood, the centre piece was stationary, the lower and upper hinged using stout leather strips. Attached to the bottom was a chain this led up to the roof to a hinged lever, attached to the other end of the lever was a rope which the blacksmith or his helper pulled down. This raised the lower chamber of the bellows, forcing air into the top chamber through a leather flap valve, raising it up, the air in the top chamber was pressurized by the weight of the wood, it then escaped through a Q iron (A large cylindrical piece of metal with a tapered hole in it) into the fire. The advantage of the double chamber bellows is that the fire is supplied with a constant jet of air. Some spade mills used powered bellows to supply the forges with air, these worked on the same principle as hair dryers, and were driven usually by a flat belt. This arrangement can be seen at the spade mill at The Ulster Folk and Transport Museum at Cultra County Down. |

||

|

|

| If

you have an interest in the industrial heritage of Ireland or in water

power, the mill is well worth a visit, it is open from. See also our page on water power in Ireland, and other surviving mills in Ireland.

|

||||

|

|

recourse was to the spade. Although some formed themselves into unofficial

groups sharing a horse and helping each other during planting and harvest,

this system found favour particularly in the west of the country, it was

called

recourse was to the spade. Although some formed themselves into unofficial

groups sharing a horse and helping each other during planting and harvest,

this system found favour particularly in the west of the country, it was

called  Spade

Mill at Templepatrick County Antrim, the site had previously been a water

powered linen mill. The advent of the motor tractor in the early twentieth

century, was the precursor to the slow decline of the industry which lasted

probably little more than two generations. During the period between 1850

to 1860 there were 33 water powered spade mills recorded in Ireland, three

of these were in County Antrim, Counties Armagh and Louth led the field

with seven.

Spade

Mill at Templepatrick County Antrim, the site had previously been a water

powered linen mill. The advent of the motor tractor in the early twentieth

century, was the precursor to the slow decline of the industry which lasted

probably little more than two generations. During the period between 1850

to 1860 there were 33 water powered spade mills recorded in Ireland, three

of these were in County Antrim, Counties Armagh and Louth led the field

with seven. of

the double chamber type, these were not original to the mill but were

donated by a gentleman from Hollywood. They were restored by Roy Meakin

using a total of four cow hides and hundreds of copper nails.

of

the double chamber type, these were not original to the mill but were

donated by a gentleman from Hollywood. They were restored by Roy Meakin

using a total of four cow hides and hundreds of copper nails.