Water Power in Ireland.Irish Water Power Home Page. |

|

| |

Types

of Water Mills. |

||

| Tuck Mill. The tuck mill was used in the woolen industry to improve the quality of the woven fabric by repeatedly combing it, producing a warm worsted fabric. Grist Mill. The name grist mill is a term which came to be used to describe a mill to which people brought their grain to be ground, the name was prevalent in the Cork area. Beetling Mill. The purpose of the beetling mill was to consolidate the woven linen cloth and to give it a sheen. You will find the beetling process described on our page about Wellbrook Beetling Mill. Spinning Mill. The spinning mill spun the fibres, be they wool, linen, or cotton into thread, ready to be woven into cloth. Before the industrial age this was done on the spinning wheel, in the past there must have been thousand of these across the land, we are currently working towards posting a video of a spinning wheel in operation on the site. Threshing Mills. These mills threshed the barley, oats or wheat removing the grain from the stalks, in some cases corn mills had a thresher installed as well as the grinding stones. One such was at Mill Farm near Newcastle County Down owned by the Holmes family. Corn Mills. Corn mills were used to grind whole grain of whatever type into flour, they were a development of the hand operated rotary quern, which prior to the development of water power in Ireland, was the only means of producing flour. Monks at Nendrum in County Down built a tide mill in about 619 AD Scutch or Flax Mills. The scutch mill was used in the linen industry to to remove the fibres from the flax stalks. You will find the process described on our page about the scutch mill at the Ulster folk and Transport Museum at Cultra County Down. |

||

|

|

Types

of Water Wheels. |

||

|

There The breast fed wheel has the water fed to it from the front and the wheel turns with the flow of the water, the power output of this is somewhat lower at about 65% The paddle type or undershot wheel utilizes a flow of water where there is no or little available head, it is like a steamboat paddle wheel and derives its power simply from the flow of water pushing the paddles around. This type of instillation would probably only deliver about 33% of the streams potential. Click to see a video of Florence Court Waterwheel in operation this is a breast fed wheel. To calculate the potential power of a river or stream you must find the volume of the flow and using this together with the available head, which is the distance the water can fall. Using the formula below you can deduce the maximum theoretical power output of the stream. The flow rate is the rate at which water travels along a flume measured in liters per second. One way to obtain an approximation of the flow rate is to throw a buoyant object into the middle of the flume, and time its travel in seconds over a known distance in meters. Then multiply by the estimated cross-sectional area of the stream, in square meters, and divide by 1000 to obtain the flow rate in liters per second. Water Power Calculations.It is probably safe to say that 12 Cub Ft (75 imperial gallons) of water falling one foot in one second would produce one horse power. Power = Head (meters) x Flow (liters per second) x 9.81 Example If the head = 60 Meters and the flow = 10 Liters second then: Power = 60 x 10 x 9.81 = 5886 watts or 5.9 kW We have a data spread sheet available with this and other formulas on it. You will need Microsoft Excel installed on your computer for it to work. Click to open or save it. |

||

|

|

Water

Turbines. |

||

|

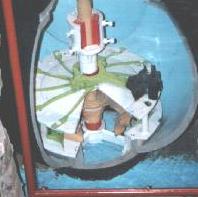

Water turbines came into use in Ireland

in the For high heads the Pelton Wheel is often used it is sometimes fabricated but most often cast, it consists of a wheel with shaped buckets around the rim, one although sometimes several high pressure jets of water are directed into the buckets causing the wheel to rotate at high speed. The illustration above shows an impulse type turbine which originally drove Patterson's Spade Mill, in it the water fills the case and is admitted to the the turbine through the guide vanes which are opened and closed by the green operating rods, this in effect is a throttle. The water passes through the rotor via angled guide vanes and exits from it tangentially forcing it to rotate, the water then exits from the bottom of the case. With the ever spiraling price of fossil fuels it would seen eminently sensible to utilize as much as possible of Ireland hydro potential, admittedly it would be small in comparison to our consumption but every little helps. If you are the owner of a derelict water mill site you might like to check out our Alternative Technology contractors page, it is likely you could make a very good long term investment, that would not only save you money, but help to save the planet also. |

||

|

|

are three basic types of waterwheel, the overshot type is where the water

is fed over the top and the wheel. This is the most efficient type and

can deliver up to 75% of the potential power of the flow.

are three basic types of waterwheel, the overshot type is where the water

is fed over the top and the wheel. This is the most efficient type and

can deliver up to 75% of the potential power of the flow. 1800's when the

power hungry linen mills sought to drive more and larger looms and spinning

machines. The turbine is particularly suited to sites where the available

fall is high, although they can be designed to utilize low head, high

volume flows using the Francis Runner which is similar to a ships propeller

set in a steel pipe.

1800's when the

power hungry linen mills sought to drive more and larger looms and spinning

machines. The turbine is particularly suited to sites where the available

fall is high, although they can be designed to utilize low head, high

volume flows using the Francis Runner which is similar to a ships propeller

set in a steel pipe.